MENU

- Home

- Products

- Marking Systems

- 125˚C CTMS - Heat Shrink Markers

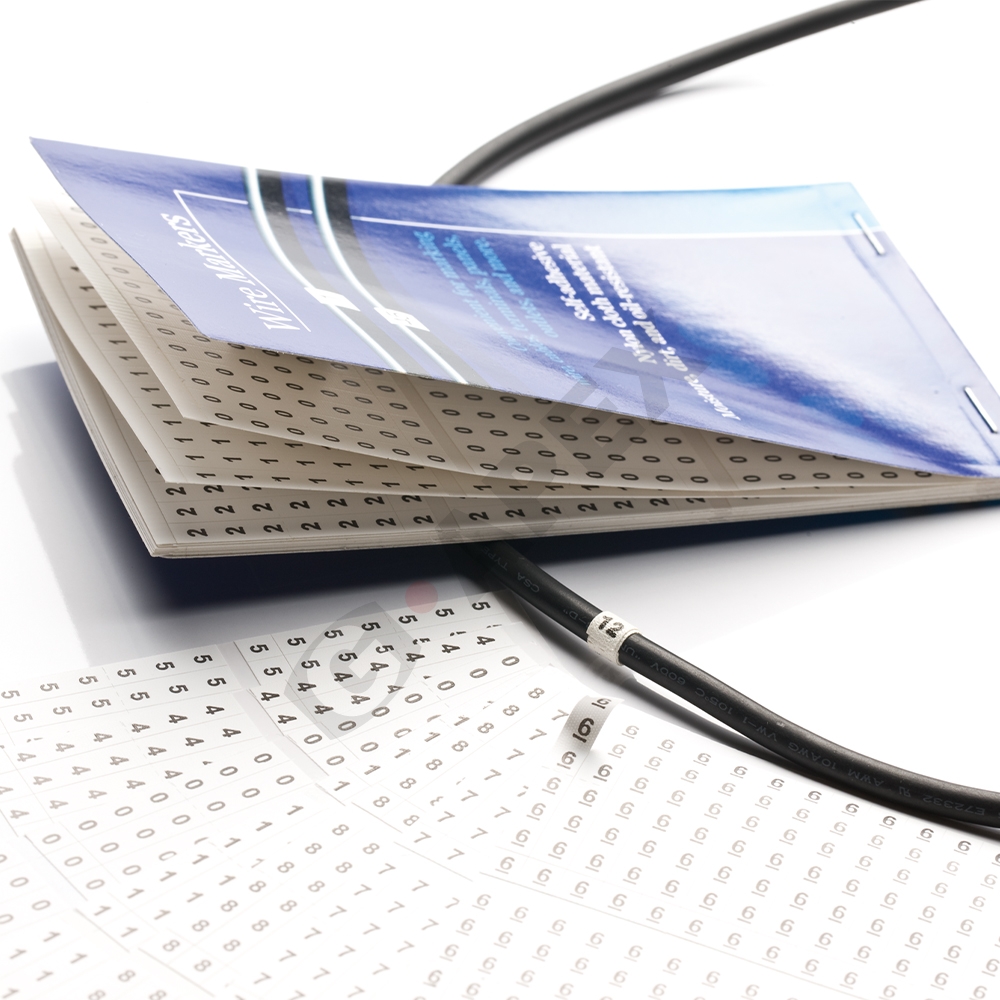

125˚C CTMS - Heat Shrink Markers

Applications

CTMS is made of high-performance polyolefin and is used in industrial, military and aerospace applications. Markers are permanent after printing and do not require an outer protective film.

Approvals / Specifications

![]() UL224 File no. E255532, 125℃ VW-1

UL224 File no. E255532, 125℃ VW-1

Operating Temperature Range

- Continuous operating temperature: -55℃ ~ 125℃

- Minimum shrink temperature: 70℃

- Full recovery temperature: Above 110˚C

Color

Standard colors: yellow and white

Characteristics

- Shrink ratio: 3:1

- Flexible, flame retardant

- Abrasion and chemical resistance

- Reliable physical, chemical and electrical performance

- Flat tubes offer ease of printing

Technical Data

| Property | Specification Requirement | Test Method | Typical Value |

|---|---|---|---|

| Longitudinal change | ≤10% | ASTM D2671 | ≤5% |

| Tensile strength | ≥10.3MPa | ASTM D2671 | ≥10.3MPa |

| Elongation at break | ≥200% | ASTM D2671 | ≥300% |

| Elongation at break after aging | ≥100% | ASTM D2671 (158˚C/168 hrs) |

≥200% |

| Heat shock | No cracking | ASTM D2671 | No cracking |

| Low temperature flexibility | No cracking | ASTM D2671 (-55˚C/4 hrs) |

No cracking |

| Dielectric voltage withstand | AC2500V/60S No breakdown |

ASTM D2671 | No breakdown |

| Dielectric strength | ≥19.7kV/mm | ASTM D2671 | ≥20kV/mm |

| Volume resistivity | ≥1014Ω‧cm | ASTM D2671 | ≥1014Ω‧cm |

| Copper corrosion | No corrosion | ASTM D2671 | No corrosion |

| Print performance | Print legible after 20 rubs Print legible after 20 strokes |

SAE AS5942 MIL-STD-202 |

Pass |

| Flammability | VW-1 | UL224 | Pass |

Specification

| Part Number | Nominal Size | As supplied (mm) | After recovered (mm) | Standard Length (Meter) |

|

|---|---|---|---|---|---|

| mm | inch | I.D.(min) | I.D.(max) | ||

| CTMS1253X0024 | 2.4 | 3/32 | 2.4 | 0.8 | 100 |

| CTMS1253X0032 | 3.2 | 1/8 | 3.2 | 1.1 | 100 |

| CTMS1253X0048 | 4.8 | 3/16 | 4.8 | 1.6 | 100 |

| CTMS1253X0064 | 6.4 | 1/4 | 6.4 | 2.1 | 100 |

| CTMS1253X0095 | 9.5 | 3/8 | 9.5 | 3.2 | 100 |

| CTMS1253X0127 | 12.7 | 1/2 | 12.7 | 4.2 | 100 |

| CTMS1253X0191 | 19.1 | 3/4 | 19.1 | 6.3 | 100 |

| CTMS1253X0254 | 25.4 | 1 | 25.4 | 8.5 | 100 |

Related Products