MENU

- Home

- Products

- Marking Systems

- 125˚C TMS - Heat Shrink Markers

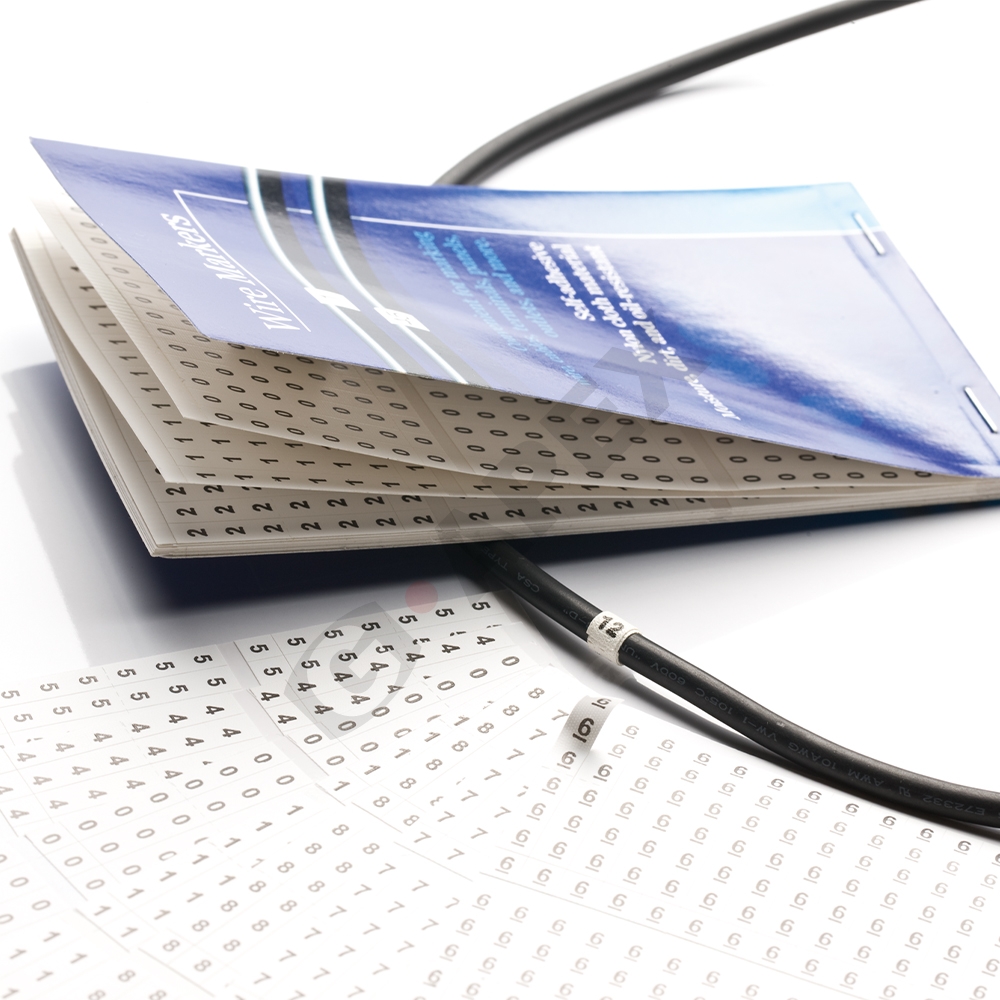

125˚C TMS - Heat Shrink Markers

Applications

Made of flame retardant polyolefin, it is a heat-shrinkable tubing specially designed for wire and cable marking. TMS has extremely flexible and thin wall characteristics, convenient for label printers to print directly, and the printing effect is permanent and legible.

Approvals / Specifications

![]() UL224 File no. E255532, 125℃ VW-1

UL224 File no. E255532, 125℃ VW-1

Operating Temperature Range

- Continuous operating temperature: -55˚C ~ 125˚C

- Minimum shrink temperature: 70˚C

- Full recovery temperature: Above 110˚C

Color

Standard colors: yellow and white

Characteristics

- Shrink ratio: 3:1

- Flexible, flame retardant

- Abrasion and chemical resistance

- Reliable physical, chemical and electrical performance

- The heat shrinkable tubing can be pre-cut with dotted lines for tearing off easily.

- Flat tubes offer ease of printing

Technical Data

| Property | Specification Requirement | Test Method | Typical Value |

|---|---|---|---|

| Longitudinal change | ≤10% | ASTM D2671 | ≤5% |

| Tensile strength | ≥10.3MPa | ASTM D2671 | ≥10.3MPa |

| Elongation at break | ≥200% | ASTM D2671 | ≥300% |

| Elongation at break after aging | ≥100% | ASTM D2671 (158˚C/168 hrs) |

≥200% |

| Heat shock | No cracking | ASTM D2671 | No cracking |

| Low temperature flexibility | No cracking | ASTM D2671 (-55˚C/4 hrs) |

No cracking |

| Dielectric voltage withstand | AC2500V/60S No breakdown |

ASTM D2671 | No breakdown |

| Dielectric strength | ≥19.7kV/mm | ASTM D2671 | ≥20kV/mm |

| Volume resistivity | ≥1014Ω‧cm | ASTM D2671 | ≥1014Ω‧cm |

| Copper corrosion | No corrosion | ASTM D2671 | No corrosion |

| Print performance | Print legible after 20 rubs Print legible after 20 strokes |

SAE AS5942 MIL-STD-202 |

Pass |

| Flammability | VW-1 | UL224 | Pass |

Specification

| Part Number | Nominal Size | As supplied (mm) | After recovered (mm) | Packing (PCS/BOX) |

|

|---|---|---|---|---|---|

| mm | inch | I.D.(min) | I.D.(max) | ||

| TMS1253X0024 | 2.4 | 3/32 | 2.4 | 0.8 | 250 |

| TMS1253X0032 | 3.2 | 1/8 | 3.2 | 1.1 | 250 |

| TMS1253X0048 | 4.8 | 3/16 | 4.8 | 1.6 | 250 |

| TMS1253X0064 | 6.4 | 1/4 | 6.4 | 2.1 | 250 |

| TMS1253X0095 | 9.5 | 3/8 | 9.5 | 3.2 | 250 |

| TMS1253X0127 | 12.7 | 1/2 | 12.7 | 4.2 | 250 |

| TMS1253X0191 | 19.1 | 3/4 | 19.1 | 6.3 | 250 |

| TMS1253X0254 | 25.4 | 1 | 25.4 | 8.5 | 250 |

Related Products